A warehouse is one of the essential aspects that determine the prosperity of your company. To

properly manage one, you need a warehouse management system.

What Is a Warehouse Management System?

A warehouse management system (WMS) is software that helps organizations to administer and manage warehouse operations such as auditing, inventory, workforce, supply chain, stock rotation and picking processes.

Warehouse management systems vary in type, complexity and implementation method. To gain the maximum benefits, find one suitable to the size and type of your warehouse. Some warehouses create their own WMS, but it is advisable to buy one from an authorized vendor.

The most popular types of WMS are cloud based systems, ERP modules and stand-alone systems.

Benefits of a Warehouse Management System

There are a huge number of benefits to implementing a warehouse management system, from improved workflow to cost savings to increased customer satisfaction. Some benefits you can expect from a WMS include:

- ERP Integration

Purchasing a warehouse management system that integrates with your business management system can help you avoid replicating procedures and systems. Also, a good WMS evolves to meet your needs as your business grows.

- Exceptional Customer Service

WMS enables real-time tracking by customers through automation. It also guarantees accuracy in picking so you make sure the products ordered are in stock and the orders are correct the first time.

- Improved Inventory Accuracy

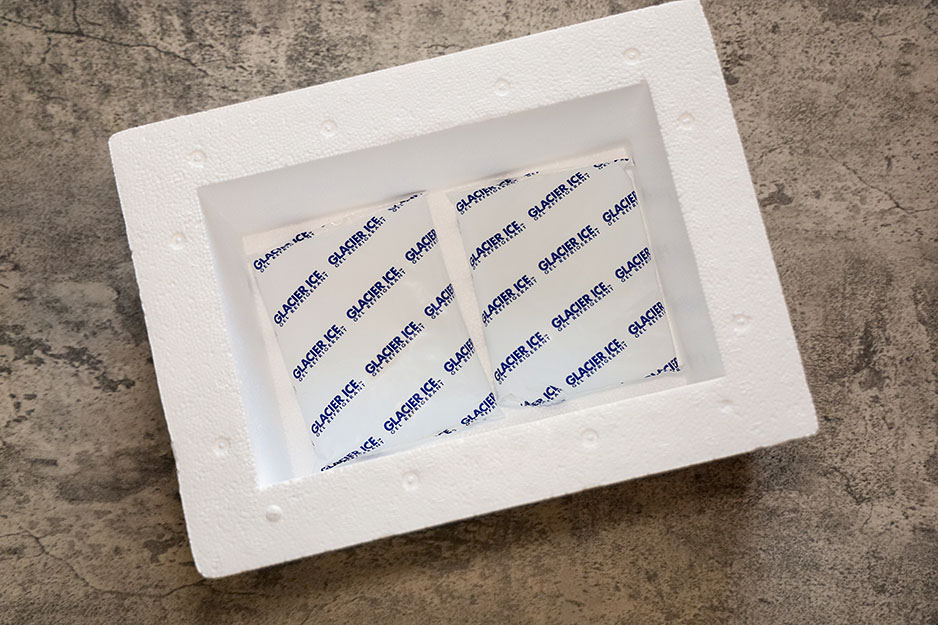

Warehouse management systems make inventory control easier, faster and more efficient. Since updates of information are in real-time, wholesalers and distributors know the location of the warehouse, what products are in it and what to replenish all the time. A WMS can also help you improve picking and packaging by monitoring the levels of styrofoam packing peanuts, cardboard boxes and air pillow packaging as part of your inventory.

- Meeting Compliance Procedures

WMS equips you with the tools to meet the government regulations, stay on top of your competition, face the challenges of the supply chain and offer quality service to your customers. A WMS also enables you to comply with the recommended warehouse safety tips for a safer work environment for your employees.

- Saves Time

Instead of the regular inventory counts which are time-consuming, you could use periodic cycle counts that can be checked against the system without sacrificing quality or accuracy. You may also be able to implement a warehouse management system with sequential picking for multi-container deliveries that combines the picking and packing areas to reduce operating time.

- Increase Company Productivity

With this system, your workers will have what they need at the right time to speed up the workflow. The system helps you move your goods at maximum speed, helping you to boost warehouse productivity and improving the fulfillment process.

- Reduction of Labor Cost

This kind of technology minimizes the workload and manpower it takes to complete tasks manually, saving you time and money. It also means your labor costs can be redirected to other important aspects of your business.

- Maximum Profits

A suitable warehouse management system ensures fewer customer inquiries and errors. Combined with the increase in company productivity, simplified customer support, time and money saved and improved sales, you will reap the maximum profit from your business.

- Mobility and Flexibility

You can monitor and manage inventory at any time and at any given place. This allows for remote working scenarios and less need for people on the warehouse floor, which can improve warehouse safety.

- Improved Billing Processes

A suitable WMS generates invoices easily, tracks orders and values, acts as a communication tool and makes accounting easier.

- Generating Automatic Reports

A warehouse management system that offers this feature means you won't struggle with fulfillment protocols, compliance or safety.

How to Choose the Right WMS

Whether you are purchasing a WMS for the first time or upgrading an existing one, choose one that meets the specific qualities and needs of your warehouse. These are the factors you should consider while choosing one:

- Advanced reporting capabilities

- Easy to use

- Compliance labeling and ASNs

- Real-time inventory update

- Integration with advanced radio-frequency technologies and barcoding

- Automated and put away an inventory report

- Scalability to accommodate business growth

- Complete back-up office integration

- Technological platform

- Total cost of ownership

- Easy accessibility via mobile, tablet, browser

- Level of technical support from vendors

It is also important to get a system within your budget. Things most likely to influence the cost of WMS include the initial implementation costs, purchase price, licensing fees and hosting fees. You may also need to budget for an annual maintenance fee if you do not have an in-house tech team.

When budgeting the cost of implementation, there are factors that impact the total price. The implementation cost may be different based on current technological systems in place, the complexity and scale of your operations, your business requirements, the number of modules to be deployed and material handling equipment and integration of processes.

Final Thoughts

A WMS can streamline your warehouse operation by automating several processes and allowing you to track and control inventory and order fulfillment in real time.

Air Sea Containers can help to further improve the productivity and safety of your warehouse facility with our range of packaging products and safety equipment. Browse our range online or contact a customer service representative at (866) 596-9448 for more information on any of our products.