Source: Chaosamran_Studio/ Shutterstock.com

Key Takeaways:- Companies that take the time to optimize packaging design achieve higher levels of customer satisfaction.

- Ensure you’re collecting valid data on the product before you design the packaging.

- The stronger and more robust your product is, the less money you’ll have to spend on protective secondary and tertiary packaging.

Why Should Your Company Adopt a Packaging Optimization Method?

Companies that take the time to optimize packaging design achieve higher levels of customer satisfaction, with clients impressed at the efficiency of delivery and the unblemished integrity of their product. If your company ships fragile items to clients around the globe, you’ll need to take extra care to use packaging that is shock-absorbent, water-resistant and tamper-proof. You’ll also cut down on overall cost when you adopt a packaging optimization system. An effective packaging design can reduce labor costs and minimize the amount of wasted space in trucks and warehouses along your company’s supply chain, consequently lowering your freight costs. Design Protective Packaging with the Suitable Shipping MaterialsTips for Optimizing Packaging Design for Cost and Supply Chain Management Efficiency

There are many simple ways to optimize packaging design that can improve the efficiency of your company’s supply chain management and make the delivery process more cost-effective.1. Make sure you’re using valid data on the product when creating the packaging.

This might sound like a simple tip, but it’s a crucial step that many manufacturers and distributors overlook when packaging products for shipment. Incorrect data can result in under-packaging, increasing your reverse logistics, or over-packaging, resulting in higher supply chain costs. Make sure you’re collecting valid data on the product before designing the packaging to ensure efficiency and cost-effectiveness.

Source: MISTER DIN/ Shutterstock.com

2. Monitor changes to international shipping regulations.

Keep up-to-date on international and national shipping regulations, using suitable shipping materials for packaging. If you don’t do this, your carrier and shipment team may not deliver them to your customers. If you ship a lot of hazardous materials and you fail to label these packages properly with hazmat labels and placards, you risk being reported to the authorities.3. Pick the right kind of packaging.

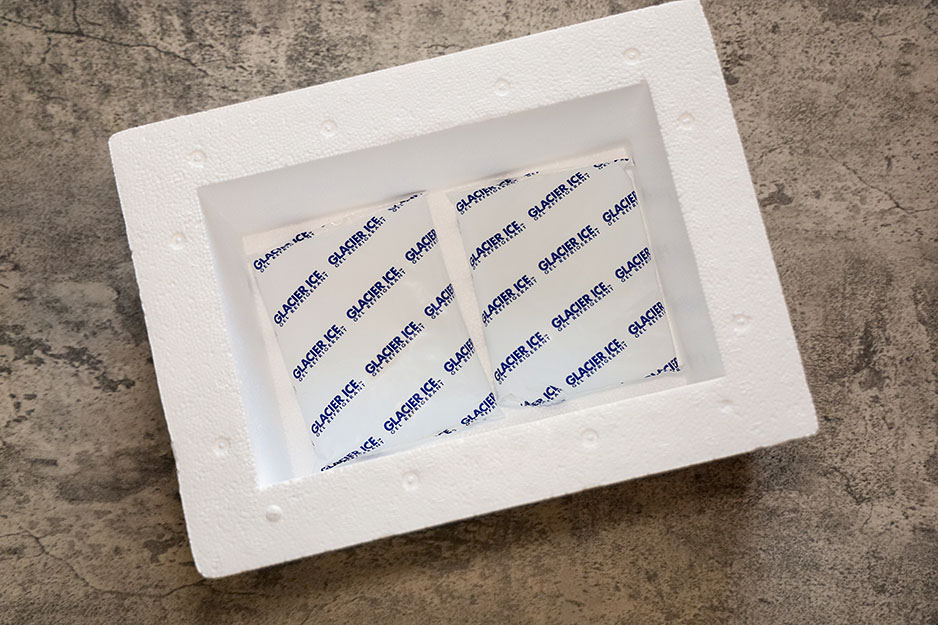

Once you’ve designed and manufactured your product, you’ll need to run a set of tests to determine how robust it is. Use the results of these tests to determine whether you should use primary, secondary or tertiary packaging materials for your package design. If your company is trying to sell a relatively durable item and promises an excellent customer experience, opt for user-friendly and ergonomic primary packaging materials. Primary packaging is typically designed with the end consumer in mind and often takes up less space during shipping, potentially reducing your freight rates. If you’re shipping products that require more protection, pick the impact-resistant and durable secondary or tertiary packaging options. These packaging types are created to withstand environmental stressors, from moisture to temperature fluctuations, as well as handling and transport hazards.4. Use a suitable amount of packaging.

To achieve a successful strategy for package optimization for your supply chain, you’ll need to pick the suitable amount of packaging for each of your products. Too little material may result in damaged products, while excess material drives up the cost of shipping. Focus on the quality of the packaging material more than the quantity. Choose a corrugated board with the proper width of flute or a styrofoam box with the ideal thickness of foam for protecting your products.5. Choose the right design for your package.

Think about the shape of your package: If you run a luxury brand that prides itself on creating a unique and refined customer experience, you might want to use curved lines and sleek accents in your package design. If you sell to customers who care about sustainability, use eco-friendly packaging. However, if your company’s top priority is to deliver a large number of products to customers safely and cost-effectively, use square and rectangular boxes that are easy to stack and store in your warehouses and carrier vans. Use Temperature-Controlled Packaging for Your Hazardous Shipments

Source: Guido Ignacio Martini/ Shutterstock.com